Solid Wood vs Engineered Wood: How to Spot the Difference When Shopping for Furniture

Table Of Contents

- Understanding Wood Types in Furniture

- What is Solid Wood Furniture?

- What is Engineered Wood Furniture?

- Visual Identification Techniques

- Weight and Density Differences

- Durability and Longevity Comparison

- Price Point Analysis

- Environmental Considerations

- Practical Tests for Shoppers

- Maintenance Requirements

- Best Uses for Each Wood Type

- Making the Right Choice for Your Home

When shopping for furniture, one of the most significant decisions you'll face is choosing between solid wood and engineered wood. While both materials can result in beautiful, functional pieces, they differ substantially in construction, durability, appearance, and price. At Loft Home Furniture, we believe that informed customers make better purchasing decisions, which is why we've created this comprehensive guide to help you distinguish between these two common furniture materials.

Understanding the difference between solid and engineered wood isn't just about knowing what you're buying—it's about ensuring you get the best value for your investment and selecting furniture that perfectly suits your lifestyle needs. Whether you're furnishing a new home or upgrading existing pieces, the ability to identify wood types will empower you to make choices that align with your quality expectations and budget.

In this article, we'll explore the defining characteristics of both solid and engineered wood, provide practical tips for distinguishing between them, and offer insight into which material might be best suited for different furniture applications in your home.

Understanding Wood Types in Furniture

Before diving into specific identification methods, it's important to understand the fundamental difference between solid and engineered wood products. Both materials serve important purposes in furniture manufacturing, but they offer different benefits and limitations that directly impact their suitability for various furniture pieces.

Wood furniture falls broadly into two categories: solid wood (made entirely from natural lumber) and engineered wood (manufactured by binding wood fibers, particles, or veneers with adhesives). Each type has distinct characteristics that influence appearance, strength, longevity, and price—all factors that matter when you're investing in furniture that you hope will last for years.

What is Solid Wood Furniture?

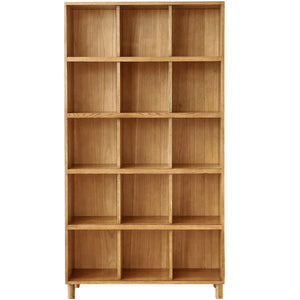

Solid wood furniture is crafted entirely from natural hardwood or softwood lumber. Each piece is cut directly from a tree trunk and processed with minimal manipulation of the natural material. Common types of solid wood used in furniture include oak, maple, walnut, cherry, mahogany, and pine, each with its own distinctive grain pattern, color, and hardness level.

The defining characteristic of solid wood furniture is that it's composed of real wood throughout—cut into the same piece. If you were to saw through a solid wood table leg, you would see the same wood grain pattern from the exterior continuing throughout the entire cross-section. This consistency is one of the most reliable indicators that you're looking at genuine solid wood.

Solid wood furniture is highly valued for several reasons. It offers exceptional durability, with many pieces lasting for generations when properly maintained. The natural beauty of wood grain creates unique, one-of-a-kind pieces that often increase in character as they age. Additionally, solid wood furniture can be refinished multiple times, allowing for restoration or style updates without replacing the entire piece.

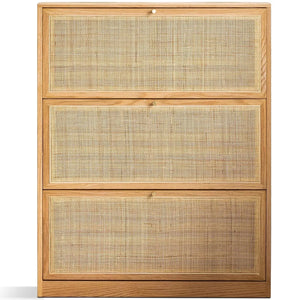

At Loft Home, our collection of wooden sofas, tables, and chairs includes carefully selected solid wood options that balance beauty, durability, and value.

What is Engineered Wood Furniture?

Engineered wood, in contrast to solid wood, is a manufactured product created by binding wood fibers, particles, or veneers together using adhesives under heat and pressure. There are several types of engineered wood commonly used in furniture production, including:

- Plywood: Made from thin sheets of wood veneer glued together with adjacent layers having their wood grain rotated relative to adjacent layers

- Medium Density Fiberboard (MDF): Composed of wood fibers combined with wax and resin binders

- Particle Board: Created from wood chips, sawmill shavings, or sawdust pressed and bound together

- Hardboard: Made from exploded wood fibers that are highly compressed

- Oriented Strand Board (OSB): Formed from wood strands arranged in specific orientations between layers

Many engineered wood furniture pieces feature a solid wood veneer on the visible surfaces—thin sheets of premium wood adhered to the engineered wood core. This provides the aesthetic appeal of solid wood while utilizing the cost and structural benefits of engineered materials.

Engineered wood offers several advantages in furniture manufacturing. It's often more affordable than solid wood, provides good dimensional stability (less warping and cracking), and can be more resistant to humidity and temperature fluctuations. It also allows for more efficient use of timber resources, as it can be produced using wood byproducts that might otherwise go to waste.

Visual Identification Techniques

One of the most reliable ways to differentiate between solid and engineered wood is through careful visual inspection. Here are key visual indicators to look for:

Examining Edge Grain Patterns

Solid wood furniture typically reveals consistent grain patterns on all edges and surfaces. If you look at the edge or underside of a table, for instance, the grain should continue naturally from the surface. In contrast, engineered wood edges often display a distinct layered appearance (in plywood) or a uniform, particle-filled edge (in MDF or particle board) that's noticeably different from the surface veneer.

Veneer Identification

Engineered wood furniture is frequently covered with a thin wood veneer to give the appearance of solid wood. Look for repeating grain patterns across different furniture pieces—an indication of veneer use, as manufacturers often cut veneers from the same wood source. Solid wood, being naturally variable, will show unique grain patterns even across matching furniture sets.

Examining Joints and Construction

The construction methods and joinery used can provide important clues about wood type. Traditional woodworking joints like dovetails, mortise and tenon, or finger joints are more commonly found in solid wood furniture due to the material's strength and workability. Engineered wood pieces more frequently utilize simpler joints, metal fasteners, or cam locks due to the material's reduced ability to hold joinery cuts.

Weight and Density Differences

The weight of furniture can be a telling indicator of its composition. Solid hardwood furniture is typically heavier than comparable pieces made from engineered wood, particularly when compared to particle board or MDF furniture. However, this distinction becomes less clear with high-density engineered products or when comparing solid softwoods (like pine) to dense engineered materials.

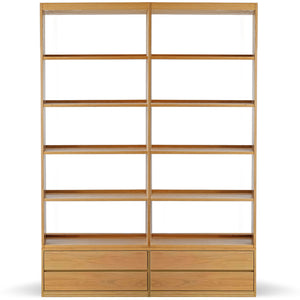

When assessing furniture in person, try lifting one end slightly (with permission at a store, of course). Solid wood pieces often feel substantially heavier and provide a sense of solidity that lighter engineered products may lack. This weight difference is particularly noticeable in larger items like dining tables and bookshelves.

Durability and Longevity Comparison

Durability is a crucial factor when investing in furniture, and there are significant differences between solid and engineered wood in this regard.

Solid wood furniture is renowned for its exceptional longevity—it's not uncommon for well-made solid wood pieces to last for generations. The material can withstand daily use and, importantly, can be sanded and refinished multiple times to remove surface damage like scratches, dents, or water rings. This repairability is a key advantage that engineered wood generally cannot match.

Engineered wood furniture, while often quite durable in its own right, typically has a more limited lifespan. The veneer surfaces on engineered wood cannot be sanded deeply for refinishing, as the thin decorative layer can be worn through to reveal the substrate below. Additionally, engineered wood—particularly lower-quality varieties—may be more susceptible to damage from moisture, which can cause swelling and structural breakdown of the internal components.

That said, modern high-quality engineered wood products have improved significantly, with some premium plywood and MDF furniture showing excellent durability for their intended uses. Many of our wooden storage solutions combine solid and engineered wood elements to balance durability with practical design.

Price Point Analysis

Price often serves as an indicator of material quality in furniture, though it's not the only factor to consider.

Solid wood furniture generally commands higher prices due to the cost of quality timber, the craftsmanship required, and its inherent longevity. These pieces represent a significant investment upfront but can offer excellent long-term value given their durability and timeless appeal. The specific wood species also affects pricing—exotic hardwoods like teak or mahogany typically cost more than domestic varieties like oak or maple.

Engineered wood furniture is usually more affordable, making it an attractive option for budget-conscious shoppers or those furnishing spaces with shorter expected use periods (like rental properties or first apartments). The manufacturing process of engineered wood is more cost-efficient and less material-intensive than harvesting and processing solid timber.

It's worth noting that price ranges can overlap significantly. High-end engineered wood furniture with premium veneers and superior construction may cost more than basic solid wood pieces made from less expensive wood species. This is why it's important to assess the actual materials and craftsmanship rather than assuming quality based on price alone.

Environmental Considerations

The environmental impact of furniture is increasingly important to many consumers, and both solid and engineered wood have different ecological footprints.

Solid wood furniture, when sourced from responsibly managed forests, can be a sustainable choice. Look for certifications like FSC (Forest Stewardship Council) that indicate the wood comes from forests managed for long-term environmental health. Solid wood's longevity also contributes to its sustainability—a piece that lasts for generations requires fewer resources over time than multiple replacements.

Engineered wood offers environmental benefits through efficient material use. By utilizing wood byproducts and requiring less timber volume per piece of furniture, engineered wood can help reduce logging pressure on forests. However, the adhesives used in some engineered wood products may contain formaldehyde or other chemicals of concern, though regulations have led to significant improvements in this area.

At Loft Home, we prioritize responsibly sourced materials across our furniture collections, including our range of wooden bed frames and other wooden furniture items.

Practical Tests for Shoppers

When shopping for furniture in person, several simple tests can help you identify material composition:

The Tap Test

Gently tap on the surface of the furniture with your knuckle. Solid wood typically produces a deeper, more resonant sound, while engineered wood often creates a duller, more hollow sound. This difference is particularly noticeable on larger flat surfaces like tabletops or cabinet sides.

The Scratch Test (Use With Caution)

In inconspicuous areas (like the underside of a table or the back of a cabinet), a very light scratch can reveal whether you're looking at solid wood or a veneer. Solid wood will show consistent material beneath the surface, while veneer-covered engineered wood will show a layer change. Note: Always ask permission before performing this test on store merchandise.

Weight Assessment

As mentioned earlier, try to gauge the weight of the piece by carefully lifting one end. Solid hardwood furniture typically feels heavier and more substantial than comparable engineered wood pieces.

Check Hidden Areas

Examine less visible areas like drawer interiors, the backs of cabinets, or the undersides of tables. Manufacturers sometimes use solid wood for visible surfaces while using engineered wood for hidden structural components—a common and cost-effective hybrid approach.

Maintenance Requirements

The care needs of solid and engineered wood furniture differ in important ways that can influence your purchasing decision.

Solid wood requires regular maintenance to preserve its beauty and integrity. This typically includes dusting with a soft cloth, cleaning with appropriate wood cleaners, and periodically applying conditioning oils or waxes to maintain moisture content. Solid wood is also more reactive to environmental conditions—it may expand and contract with humidity and temperature changes, requiring stable indoor conditions for optimal longevity.

Engineered wood generally requires less intensive maintenance. The factory finishes on most engineered wood furniture are quite durable and need only regular dusting and occasional cleaning with a damp cloth. However, these pieces are more vulnerable to water damage—particularly particle board—which can cause irreversible swelling and breakdown of the material.

Both types of furniture should be protected from direct sunlight, which can fade finishes over time, and from extreme heat sources that could damage the wood or finishes.

Best Uses for Each Wood Type

Different furniture applications may be better suited to either solid or engineered wood based on their inherent properties.

Solid wood excels in applications where durability, longevity, and aesthetic appeal are paramount. It's particularly well-suited for:

- Dining tables that will see daily use

- Heirloom-quality pieces intended to last generations

- Statement furniture where the natural beauty of wood grain is a key design element

- Items that may need refinishing over time

- Bed frames that require structural integrity

Engineered wood shines in scenarios where dimensional stability, cost-effectiveness, or certain design features are priorities:

- Large flat surfaces like cabinet sides that could warp if made from solid wood

- Furniture for humid environments where solid wood might experience excessive movement

- Budget-friendly options for first homes or temporary living situations

- Pieces with intricate carved details that would be prohibitively expensive in solid wood

- Modern designs with smooth, uniform surfaces

Many furniture manufacturers, including Loft Home, offer hybrid pieces that strategically use both materials—solid wood for structural components and wear surfaces, with engineered wood for internal elements and large flat panels. This approach balances durability, stability, and cost.

Making the Right Choice for Your Home

When deciding between solid and engineered wood furniture, consider these key factors:

Budget: Determine what you can afford to spend, keeping in mind that quality solid wood represents a longer-term investment while engineered wood offers more affordable options.

Intended Use: Consider how the furniture will be used. High-use items that will face wear and tear might justify the investment in solid wood, while less frequently used pieces might be suitable in engineered wood.

Longevity Expectations: If you're looking for furniture that will last decades or be passed down as heirlooms, solid wood is generally the superior choice. For shorter-term needs, engineered wood can provide good service.

Aesthetic Preferences: Both materials can be beautiful, but solid wood offers unique grain patterns and develops a patina over time that many people value. Modern engineered wood furniture can achieve a wide range of finishes and looks that might appeal to different design sensibilities.

Environmental Conditions: Consider your home's humidity levels, temperature fluctuations, and exposure to sunlight. These factors may influence which material will perform better in your specific environment.

At Loft Home Furniture, we offer a carefully curated selection of both solid and engineered wood furniture across our collections, ensuring you can find pieces that match your needs for quality, style, and value.

Understanding the differences between solid wood and engineered wood furniture empowers you to make informed purchasing decisions that align with your budget, lifestyle, and aesthetic preferences. While solid wood offers exceptional durability, unique natural beauty, and the potential for refinishing, engineered wood provides advantages in terms of cost, stability, and consistency.

Both materials have legitimate places in quality furniture manufacturing, and many excellent pieces incorporate both—using solid wood where strength and visibility matter most, and engineered wood where stability and cost-efficiency are priorities.

When shopping for wooden furniture, take time to examine construction details, ask questions about the materials used, and consider how the piece will function in your home over time. By applying the identification techniques and considerations we've discussed, you'll be well-equipped to select furniture that offers the best combination of beauty, functionality, and value for your specific needs.

Remember that quality furniture is an investment in your home environment. Whether you choose solid wood for its longevity and natural character or engineered wood for its stability and value, selecting well-made pieces from reputable manufacturers will ensure your satisfaction for years to come.

Explore Loft Home's collection of premium wooden furniture to find the perfect pieces for your home, crafted with attention to quality, design, and value.

Leave a comment