Teak Oil vs Water-Based Sealer: 12-Month Performance Results and Which to Choose

Table Of Contents

- Introduction

- Understanding Wood Finishes: Teak Oil and Water-Based Sealers

- 12-Month Comparison: Performance Results

- Appearance After 12 Months

- Protection Capabilities

- Maintenance Requirements

- Environmental Considerations

- Application Process and Ease of Use

- Cost Analysis: Initial Investment vs. Long-Term Value

- Furniture-Specific Recommendations

- Conclusion: Making Your Decision

Choosing the right finish for your wooden furniture can significantly impact both its appearance and longevity. Among the most popular options are teak oil and water-based sealers, each with distinct properties and performance characteristics. At Loft Home Furniture, we understand that furniture is an investment, and protecting that investment requires informed decisions about maintenance and care.

Whether you've recently purchased a beautiful wooden table or are looking to refresh your existing wooden sofas, knowing which finish will best preserve and enhance your furniture over time is crucial. That's why we conducted a comprehensive 12-month performance comparison between teak oil and water-based sealers, documenting real-world results across various conditions and furniture types.

In this detailed comparison, we'll explore how each finish performs over a full year of use, examining aspects like appearance retention, protection capabilities, maintenance requirements, environmental impact, application process, and cost efficiency. By the end, you'll have all the information you need to make an informed choice for your specific wooden furniture pieces.

Teak Oil vs Water-Based Sealer

12-Month Performance Comparison

Teak Oil

- Rich, warm appearance enhancing wood grain

- Requires reapplication every 3-4 months

- Moderate moisture resistance that diminishes over time

- Minimal UV and scratch protection

- Higher VOC emissions during application

Water-Based Sealer

- Clear finish preserving wood's natural color

- Maintenance typically every 2-5 years

- Superior moisture resistance throughout testing period

- Effective UV and scratch protection

- Low VOCs with minimal environmental impact

Protection Performance After 12 Months

Moisture Resistance

UV Protection

Scratch Resistance

Maintenance Timeline

Furniture-Specific Recommendations

Dining & Kitchen Tables

High-Traffic Furniture

Outdoor Furniture

Vintage/Character Pieces

Final Verdict

After 12 months of testing, water-based sealers demonstrate superior protection, durability, and lower maintenance requirements for most furniture applications. While teak oil offers aesthetic advantages with its rich, warm appearance, its practical disadvantages make it best suited for decorative or low-use pieces where regular maintenance is manageable.

Cost Efficiency

Though water-based sealers have a higher initial cost (₹25-60 per quart vs ₹15-30 for teak oil), their longer protection duration makes them more economical over time. The reduced maintenance frequency also translates to significant time savings over your furniture's lifespan.

Understanding Wood Finishes: Teak Oil and Water-Based Sealers

Before diving into the 12-month performance results, it's essential to understand what teak oil and water-based sealers are and how they fundamentally differ from each other.

What is Teak Oil?

Teak oil is not actually oil extracted from teak trees, as the name might suggest. Rather, it's a blend of various oils (typically linseed or tung oil) and solvents designed to penetrate wood fibers. Originally formulated for teak furniture, this finish has become popular for various hardwoods. Teak oil penetrates deeply into wood, enhancing its natural grain pattern and color while providing a moderate level of moisture resistance.

The defining characteristic of teak oil is its ability to become part of the wood rather than forming a distinct layer on top. This integration with the wood fibers creates a natural, matte to satin finish that many furniture enthusiasts appreciate for its authentic appearance.

What are Water-Based Sealers?

Water-based sealers represent a more modern approach to wood protection. These finishes use water as a carrier for acrylic or polyurethane resins that form a protective film on the wood's surface. Unlike oil-based products, water-based sealers emit fewer VOCs (Volatile Organic Compounds), making them more environmentally friendly and less odorous during application.

The primary function of water-based sealers is to create a protective barrier that prevents moisture, UV radiation, and daily wear from directly contacting the wood. These sealers typically produce a clear finish that ranges from matte to glossy, depending on the specific product formulation.

12-Month Comparison: Performance Results

Our 12-month assessment involved applying teak oil and water-based sealers to identical pieces of wooden furniture, including dining tables, coffee tables, and outdoor furniture. These pieces were exposed to regular household use, varying humidity levels, occasional direct sunlight, and normal cleaning procedures. Here's what we observed after a full year:

Appearance After 12 Months

Teak Oil Results

After 12 months, furniture treated with teak oil demonstrated a rich, warm patina that many would describe as an enhanced natural appearance. The wood grain remained highly visible and tactile, with the finish integrating seamlessly with the wood structure. However, we observed some notable changes:

The color deepened considerably in most wood species, creating an amber hue that many find attractive in traditional and rustic furniture styles like those in our rustic tables collection. Areas with frequent handling or use (such as armrests or tabletops) showed some inconsistency in finish, with more frequently touched zones appearing slightly duller than less-used areas. Furniture pieces placed in rooms with significant sunlight exposure exhibited some uneven coloration, with sun-exposed sections darkening more rapidly.

Water-Based Sealer Results

Furniture finished with water-based sealers maintained a more consistent appearance throughout the 12-month period. The initial finish clarity remained largely unchanged, with the wood's natural color preserved rather than enhanced or deepened. The protective layer remained intact on most surfaces with these key observations:

The finish maintained excellent clarity without the amber tinting common to oil-based products, making it particularly suitable for light-colored woods like those used in our Scandinavian tables. High-traffic areas showed minimal changes compared to less-used surfaces, with the protective film providing consistent wear resistance. Some minor scratching was visible on heavily used surfaces, though this was primarily in the finish layer rather than the wood itself.

Protection Capabilities

Moisture Resistance

One of the critical functions of any wood finish is moisture protection. Our 12-month test revealed significant differences between the two finishes:

Teak Oil: Provided moderate moisture resistance initially, but this protection diminished gradually over time. By the 12-month mark, water droplets left on the surface for more than a few minutes occasionally resulted in slight discoloration or raised grain. This was particularly evident in bathroom furniture and kitchen-adjacent pieces.

Water-Based Sealer: Maintained excellent moisture resistance throughout the entire testing period. Even after 12 months, water beaded effectively on the surface without penetrating. This superior moisture protection makes water-based sealers particularly suitable for dining tables and bathroom furniture where water exposure is common.

UV Protection

Extended exposure to sunlight can cause significant damage to wooden furniture through UV radiation:

Teak Oil: Provided minimal UV protection, with noticeable fading and color changes in areas exposed to direct sunlight. Furniture pieces placed near windows showed uneven coloration after 12 months, with sun-exposed sections typically darkening more than shaded areas.

Water-Based Sealer: Most modern water-based sealers contain UV inhibitors, and our testing confirmed their effectiveness. Furniture finished with these sealers showed significantly less sun-related fading and color shifting, maintaining more consistent appearance regardless of placement within the room.

Scratch and Wear Resistance

Daily use inevitably subjects furniture to potential scratches and wear:

Teak Oil: Offered minimal protection against physical damage. Scratches and dents readily transferred to the wood itself since the oil penetrates rather than creating a protective surface layer. However, minor surface scratches were often less visible due to the finish's integration with the wood.

Water-Based Sealer: Provided superior scratch resistance through its protective film. When scratches did occur, they frequently affected only the finish layer rather than the underlying wood. This made repairs easier and protected the wood's structural integrity, particularly important for frequently used items like coffee tables.

Maintenance Requirements

The long-term maintenance needs of each finish type significantly impact the overall ownership experience and should be factored into your decision-making process.

Teak Oil Maintenance

Furniture finished with teak oil required more frequent maintenance to maintain optimal appearance and protection. Our 12-month observations revealed:

Reapplication was necessary approximately every 3-4 months to maintain proper protection and appearance, with high-use furniture pieces sometimes requiring even more frequent attention. The reapplication process involved light sanding and cleaning before applying new oil, requiring moderate effort but minimal specialized skills. Each maintenance session typically took 1-2 hours per furniture piece, depending on size and complexity.

The advantage of teak oil maintenance is that it doesn't require complete removal of previous applications. New applications blend with existing finish, and localized touch-ups are possible for areas showing more wear without refinishing the entire piece.

Water-Based Sealer Maintenance

Furniture with water-based sealers demonstrated significantly different maintenance patterns:

No reapplication was required within the 12-month testing period for most pieces, though some heavily used surfaces showed early signs of wear that might necessitate refreshing within the next 6-12 months. Routine cleaning with mild soap and water was sufficient to maintain appearance without special products. When eventual reapplication becomes necessary, the process is more involved than with oil, typically requiring removal of the old finish layer before applying a new one.

While less frequent, water-based sealer maintenance tends to be more labor-intensive when required. However, for most residential furniture applications, this translates to maintenance every several years rather than several times per year.

Environmental Considerations

Modern consumers increasingly consider environmental impact when selecting products for their homes, making this an important dimension in our comparison.

VOC Emissions and Air Quality

Teak Oil: Traditional teak oil formulations contain relatively high levels of VOCs (Volatile Organic Compounds) that release into the air during application and curing. These emissions can affect indoor air quality and may cause respiratory irritation for sensitive individuals. Our testing noted persistent odors for 3-5 days after application, requiring good ventilation during and after the finishing process.

Water-Based Sealer: These products typically contain significantly lower VOC levels, with some modern formulations approaching zero-VOC status. During our testing, odors dissipated within hours rather than days, and application could be safely conducted with minimal ventilation concerns. This makes water-based sealers particularly suitable for furniture used in bedrooms and other enclosed spaces where air quality is especially important.

Sustainability Factors

Teak Oil: Traditional oil-based products often contain petroleum derivatives and are typically less sustainable in their production processes. However, some newer formulations incorporate renewable resources such as plant oils, improving their environmental profile.

Water-Based Sealer: Generally recognized as the more environmentally friendly option due to lower toxicity, reduced VOCs, easier cleanup without harsh solvents, and frequently more sustainable manufacturing processes. Many water-based products now carry environmental certifications that oil-based alternatives cannot meet.

Application Process and Ease of Use

The practical experience of applying each finish type differs considerably, which may influence your choice depending on your comfort level with DIY projects and available time.

Teak Oil Application

Teak oil offers a relatively forgiving application process suitable for DIY enthusiasts:

Application tools include simple rags or soft cloths, without requiring specialized equipment. The finish is applied by rubbing the oil into the wood grain, waiting for absorption (typically 15-30 minutes), and wiping away excess oil. Multiple coats (usually 2-3) are recommended for optimal results, with light sanding between coats. The entire process for a typical coffee table takes approximately 4-6 hours, including drying time.

The main advantage of teak oil application is its error-forgiveness—drips or uneven application can be easily corrected by simply wiping the surface, and the finish blends naturally without visible lap marks or brush strokes.

Water-Based Sealer Application

Water-based sealers require a somewhat more technical approach:

Application typically requires brushes, rollers, or spray equipment depending on the specific product and desired finish quality. The sealer must be applied in thin, even coats to prevent drips, bubbles, and visible application marks. Drying time between coats is faster than oil (typically 2-4 hours), but the overall process requires more attention to technique. Most applications require 2-3 coats for optimal protection, with light sanding between coats for proper adhesion.

While slightly more demanding in technique, water-based sealers offer advantages including faster project completion due to shorter drying times and easier cleanup with just soap and water rather than chemical solvents.

Cost Analysis: Initial Investment vs. Long-Term Value

When considering the economics of each finish option, we need to evaluate both initial costs and long-term expenses associated with maintenance and reapplication.

Initial Investment

Teak Oil: Typically represents the lower initial investment, with quality products ranging from $15-30 per quart. One quart typically covers 100-150 square feet, sufficient for multiple furniture pieces. The application tools (rags, cloths) add minimal additional cost.

Water-Based Sealer: Generally commands a higher price point, with quality products ranging from $25-60 per quart. Coverage is similar to teak oil at approximately 100-150 square feet per quart. Additional costs may include proper application tools like fine brushes or specialized applicators.

Long-Term Costs

Looking beyond the initial application reveals a different economic picture:

Teak Oil: The more frequent reapplication schedule (3-4 times per year) means that over a 5-year period, the total product cost often exceeds that of water-based alternatives, despite the lower initial price point. Additionally, the time investment for regular maintenance should be factored into the overall cost consideration.

Water-Based Sealer: While more expensive initially, the significantly longer interval between required reapplications (typically 2-5 years depending on usage) results in lower long-term material costs. The reduced maintenance frequency also translates to time savings over the furniture's lifespan.

For furniture representing a significant investment, such as a quality dining table or premium wooden sofa, the protection offered by each finish should also be considered as a factor in preserving the furniture's value over time.

Furniture-Specific Recommendations

Different furniture types and usage scenarios may benefit from specific finish choices based on our 12-month performance observations.

Dining and Kitchen Tables

Recommended Finish: Water-based sealer

Dining surfaces require superior protection against moisture, food stains, and frequent cleaning. Water-based sealers create a more impermeable barrier that prevents liquids from reaching the wood, making cleanup easier and reducing the risk of staining or water damage. This is particularly important for dining tables, which encounter everything from hot dishes to spilled drinks.

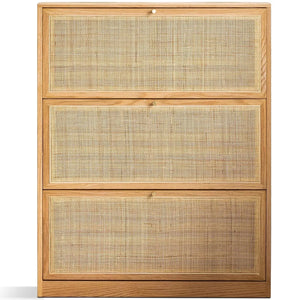

Decorative or Display Furniture

Recommended Finish: Either option, with preference based on desired appearance

For pieces like side tables, display shelves, or decorative storage pieces that receive minimal handling, the choice can be based primarily on aesthetic preference. Teak oil enhances grain patterns and creates a warmer appearance, while water-based sealers preserve the wood's original color with minimal amber tinting.

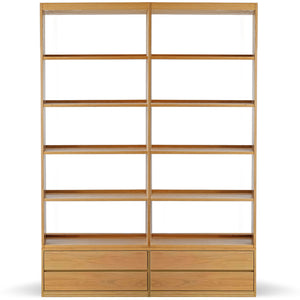

High-Traffic Furniture

Recommended Finish: Water-based sealer

For frequently used pieces like coffee tables, bookshelves with adjustable shelves, or furniture in family rooms, the superior wear resistance and lower maintenance requirements of water-based sealers provide practical advantages that typically outweigh aesthetic considerations.

Outdoor or Humid Environment Furniture

Recommended Finish: Specialized water-based exterior sealer

For furniture used outdoors or in humid environments like bathrooms, specialized water-based exterior sealers with enhanced UV protection and mold/mildew resistance offer the best long-term protection. Standard teak oil, despite its name and association with marine applications, doesn't provide adequate protection for truly outdoor applications without very frequent maintenance.

Vintage or Character Furniture

Recommended Finish: Teak oil

For vintage tables or pieces where enhancing character and wood grain is the primary objective, teak oil offers advantages in bringing out depth and patina that many find appealing. The additional maintenance requirements may be worthwhile for showcase pieces where the rich, natural appearance is the priority.

Conclusion: Making Your Decision

After 12 months of comparative testing, our results show that both teak oil and water-based sealers offer distinct advantages that make them suitable for different applications and preferences.

Choose teak oil when:

You desire a rich, natural finish that enhances wood grain and creates depth and warmth. You're willing to perform regular maintenance every few months to maintain appearance and protection. You prefer a traditional approach to wood finishing with a matte to satin appearance. The furniture piece has historic or rustic aesthetic value that would be enhanced by a more traditional finish. You're comfortable with the application process of hand-rubbing oil into the wood.

Choose water-based sealer when:

Maximum protection against moisture, UV damage, and physical wear is a priority. You prefer minimal maintenance requirements over several years rather than frequent reapplications. Lower VOCs and environmental impact are important considerations for your home. The furniture will be subjected to heavy use, food contact, or potential spills. You want to preserve the wood's original color without significant amber tinting. You need a finish that dries quickly and has minimal odor during application.

Ultimately, both finishes can provide excellent results when properly applied and maintained. Your specific furniture pieces, usage patterns, aesthetic preferences, and willingness to perform maintenance will determine which option better suits your needs. For valuable furniture investments, the additional protection offered by water-based sealers often justifies the higher initial cost through reduced maintenance and better long-term preservation of the furniture's condition and value.

At Loft Home Furniture, we're committed to helping you protect and maintain your furniture investment. Whether you've purchased one of our wooden tables or are caring for heirloom pieces, proper finishing and maintenance will ensure years of beauty and function from your wooden furniture.

Explore our collection of premium wooden tables, wooden sofas, and other quality wooden furniture pieces at Loft Home Furniture. Our expert team is always available to provide guidance on furniture care and maintenance to ensure your pieces remain beautiful for years to come.

Leave a comment